As supply chain visibility increases, businesses are seeing the value of streamlining their delivery and logistics procedures to maintain their competitiveness. There are five stages of logistics maturity, with stage five being the most advanced, according to Gartner’s maturity curve, when logistics and the rest of the supply chain collaborate to take advantage of untapped commercial opportunities. However, due to difficulties connecting participants across the value chain and gaining access to decision-grade data, many businesses are still mired in earlier stages. These issues can be resolved by switching from an app-to-app architecture to an open platform architecture, which enables companies to make quick, profitable decisions, carry them out smoothly, and learn from them.

Supply chains are becoming more complicated as the globe gets more interconnected, with several parties taking part in the creation, delivery, and distribution of goods and services. Businesses must improve their delivery and logistics procedures to be competitive, which calls for increased transparency, teamwork, and integration throughout the whole value chain. However, many organizations are struggling to optimize their supply chain due to a lack of integration, standardization, and visibility.

This paper discusses the five stages of logistics maturity as per Gartner’s maturity curve and highlights the challenges organizations face in attaining stages four and five.

The Five Stages of Logistics Maturity: Gartner’s Logistics Maturity Curve outlines the five stages of logistics maturity that businesses go through as they develop their logistics capabilities.

These stages are:

1. React – Siloed Autonomous Operations

2. Anticipate – Functional Scale and Efficiency

3. Integrate – Integrate the Supply Chain functions

4. Collaborate – Work jointly with others in the Value Chain

5. Orchestrate – Network Orchestrator of Profitable Customer Value

At the React stage, businesses have autonomous departments driving logistics priorities via manual processes and disconnected systems, leading to little coordination and cross-department standardization. At the Anticipate stage, centralization of the logistics function improves efficiency and productivity, with a focus on creating standardized processes and methods to benefit from economies of scale. The Integrate stage sees a focus on integrating the logistics function into the overall supply chain, considering how logistics will affect customer service, procurement, and manufacturing. At the Collaborate stage, logistics is an integrated part of a shared supply chain management vision, with collaboration and visibility with suppliers and customers. The Orchestrate stage sees logistics and the rest of the supply chain facilitating processes across an ecosystem of partners to capitalize on unexploited business opportunities, enabling broader visibility and timely, fact-based decisions.

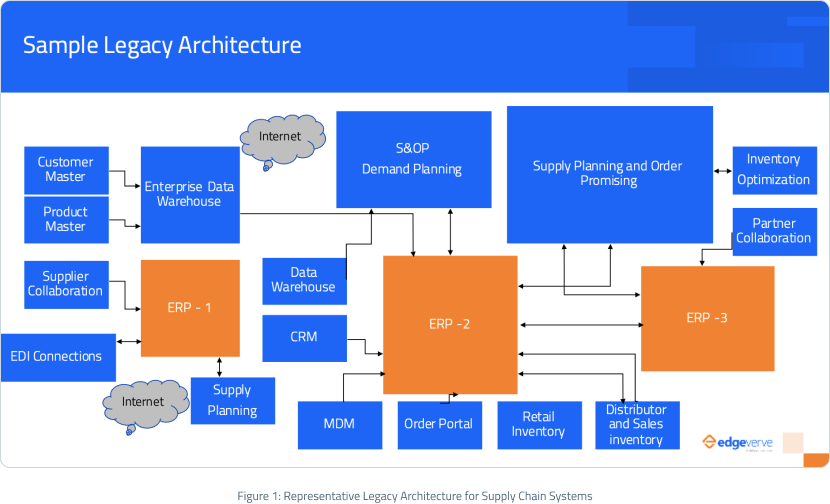

The ability to acquire decision-grade data is one of the main obstacles to achieving stages four and five. Fundamental issues with the data are its accuracy, harmonization, and correlation. The legacy “point-to-point” architecture’s data is segregated, latent, unconnected, and out of harmony. Each link in the value chain has a unique system or application, which increases complexity. People think they must alter all the apps from a technology/IT standpoint, making change slower and connecting players throughout the value chain even more difficult.

By switching from an app-to-app architecture to an open platform architecture, this problem can be solved. Businesses will be able to make decisions quickly, create alignment both within and outside the organization, and act quickly and profitably in the right direction as a result.

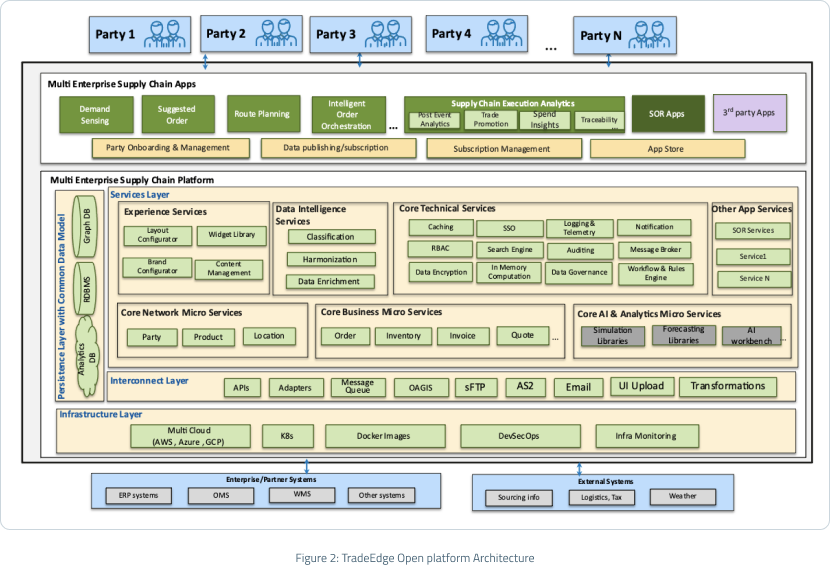

An open platform architecture improves visibility, decision-making, and collaboration across the supply chain ecosystem by eliminating data silos and enabling bidirectional data flow. It gives organizations the freedom to scale up and customize their systems, promotes innovation through outside collaborations, and equips them with the tools they need to run more effectively, respond to change, and improve supply chain efficiency. Businesses should concentrate on visibility, correlation, and execution, three vital areas, to do this, as each is essential to gaining the advantages of an open platform design.

1. Visibility

An open platform design allows for more visibility across the ecosystem, reaching various players including contract manufacturers, suppliers, logistics service providers, and buyers and sellers via many channels. Clarity within the data involves being able to distinguish between important insights and noise. Data must be accessible across the ecosystem, bidirectional, and without any lag. To ensure that participants may access and contribute to the data at their respective points in the supply chain, open platforms use extremely flexible through adaptable connectivity options. Techniques for transforming data also reduce the need for significant changes to participants’ underlying systems, allowing for seamless integration. Effective data visualization at the right granularity and frequency levels increases visibility and facilitates decision-making.

2. Correlation

Correlating various data sources is a crucial aspect of an open platform architecture. Businesses may analyze and comprehend the cause-and-effect correlations between multiple data points by utilizing the ecosystem’s interconnectedness. For instance, comparing sales data to inventory levels and manufacturing plans can reveal how choices affect business operations. Using analytics tools, these connections may be visualized, enabling companies to spot trends, bottlenecks, and chances for improvement. An open platform architecture makes it possible to integrate and correlate data from many systems, giving rise to a comprehensive picture of the dynamics of the supply chain.

3. Execution

Achieving successful execution requires not just understanding the data but also successfully using it. The idea of network apps, which run over-the-top (OTT) on a shared data model, is provided by open platform designs. These applications serve as mediators, permitting multi-party transactions without bias and guaranteeing execution that is both fair and effective. Businesses may execute tasks, make decisions, and learn from the results in a collaborative way by utilizing network apps. This strategy encourages the ecosystem to be agile, adaptable, and innovative because network apps can be created by outside partners by utilizing their knowledge and solutions.

In summary, an open platform design helps firms overcome obstacles in the supply chain environment by enhancing visibility, enabling data correlation, and empowering efficient execution. By providing highly flexible and adaptable connectivity options, facilitating seamless data transformation, and supplying data visualization capabilities, this architecture incorporates participants in a non-intrusive way. Network apps that use a common data model (CDM) which improves performance by serving as impartial brokers for multi-party transactions. Businesses may unleash the full potential of their supply chain ecosystem and get better results by embracing the principles of openness.

A strong tool like TradeEdge Network can assist companies in achieving these objectives. TradeEdge Network can provide companies with the tools and resources they need to improve their supply chain.

Loved what you read?

Get practical thought leadership articles on AI and Automation delivered to your inbox

Loved what you read?

Get practical thought leadership articles on AI and Automation delivered to your inbox

Adopting an open platform architecture will enable businesses to take decisions quickly, build alignment within and outside the company, and act quickly and profitably in the right direction. This will lead to the following business outcomes:

1. Enhanced effectiveness and output

2. Better client service and encounter

3. Cost savings and increased profitability

4. Improved risk mitigation and management

5. Increased collaboration and supply chain visibility

6. Greater market share and expansion possibilities

Disclaimer Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the respective institutions or funding agencies